Our new brew kettle

It’s been a busy, somewhat nerve wracking but ultimately very exciting couple of weeks for us here at Abbeydale Brewery as we’ve successfully commissioned a brand new brew kettle! The kettle is an absolutely crucial piece of our brewkit, used for every single beer we’ve ever made (except for that one raw ale created for our Funk Dungeon project!), so this is a really important development here at Abbeydale HQ. Our previous kettle had been with us since 2009, and used for literally thousands of brews – the hope is that our new kettle will see us through just as many years and provide a considerable upgrade to our brewing capabilities.

The kettle has travelled a whopping 14,000km from China to reach us here in Sheffield, and we were able to track the progress of our new vessel on its voyage across the seas, which Pat in particular watched with keen interest! The changeover of kit meant we were unable to brew for ten days whilst the installation took place – the longest break we’ve had since the very early days of the brewery. To counter this, in the weeks leading up the anticipated arrival of the new kettle, our brewteam ramped up production, ensuring that every single tank was full before the old kettle was decommissioned. And we haven’t run out of Moonshine, so we’re definitely calling that a job well done!

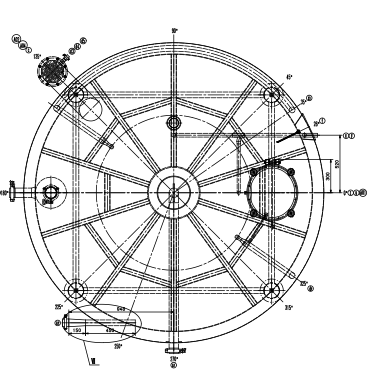

The project was undertaken with our suppliers SSV, who designed and commissioned our new piece of kit, working closely with us throughout the whole process. Although we’re currently keeping our batches the same volume while we get used to how everything works, the new kettle is almost twice the size of the previous one, with a working capacity of 6000l.

Our new kettle is more energy efficient than its predecessor – it has a built in vapour condensing unit which recovers energy, meaning we can capture the heat from the steam used for boiling our wort and recycle water at 95 degrees back to our hot liquor tank, ready for the next brew.

A built in whirlpool separates the flocculated proteins (trub) and additional hop matter from the wort, which should help us to create a cleaner flavour profile and clearer beer more easily. The whirlpool also includes the potential to more quickly chill the wort down to 80 degrees (any surplus cold liquor used for chilling here is also able to be recycled as hot liquor for the next brew), which can reduce hop isomerisation where desired, making it that bit more straightforward for us to brew beers with a lower bitterness but just as much delicious flavour. We will be using more hop pellets as a result – these are less absorbent to wort than whole leaf cones, meaning a higher yield in fermenter. Overall, the whirlpool gives us another way to experiment with hop additions and provides greater flexibility in terms of beer flavour and production for our brewteam to experiment with.

The external wort boiler is another new component to our kit, which can increase the efficiency of isomerisation due to a more active and higher temperature boil. This also helps prevent caramelisation, which is perfect for those light and crisp pale ales that we’re so well known for.

By heating wort in the external wort boiler (EWB), cooler (99 degree) wort is taken from the bottom of the kettle into the EWB, which is then heated by steam to 103 degrees and pushed out of the distribution plate back onto the wort at the top of the kettle. A thermosiphon current is thus formed, without the need for a pump. As well as reducing energy consumption and preventing too much agitation of the wort, it also looks pretty cool (#science)!

Finally, our brewers have access to lots more feedback on how the brew is progressing, with a plethora of more sophisticated sensors giving our team more detailed data across parameters such as flow rates, temperatures and volumes, ensuring more control and therefore more consistency than ever before. All this information is displayed on a swish new control panel, which has further potential for upgrading into our existing milling equipment in the future too.

The first brew on the new kettle was, of course, Moonshine, and the team are now starting to put it through its paces with some new specials as well! We’re excited to announce that our Deliverance collaboration with Yakima Chief, a 7% IPA featuring Sabro, Talus, and experimental hop HBC 472, was the first brew using the new whirlpool to its full potential. This beer is one of highest rated of all time, and we can’t wait to see it making another appearance on our availability lists very soon!

Cheers,

Team Abbeydale